Improving Foundation Strength with Detailed Steel Layouts

Strong foundations are the heart of every safe structure. Whether it’s a home, a commercial building, or a large public facility, the stability of the entire project depends on how well the base is planned and reinforced. Engineers, contractors, and designers across the United States know this well. That’s why they invest so much time in planning how reinforcement steel should be arranged before a project even begins.

Today, digital tools and detailed steel layouts are transforming the way foundation work is handled. They help prevent mistakes, improve safety, and ensure that each structural element performs the way it should. When a project involves rebar for footing, these tools become even more valuable because footings carry the weight of everything above them.

Accurate layouts make the work more predictable. They also help project teams avoid costly rework later. And with construction costs steadily rising across many regions in the United States, avoiding unnecessary waste has become essential. This makes early planning not only a smart approach but also a cost-friendly one.

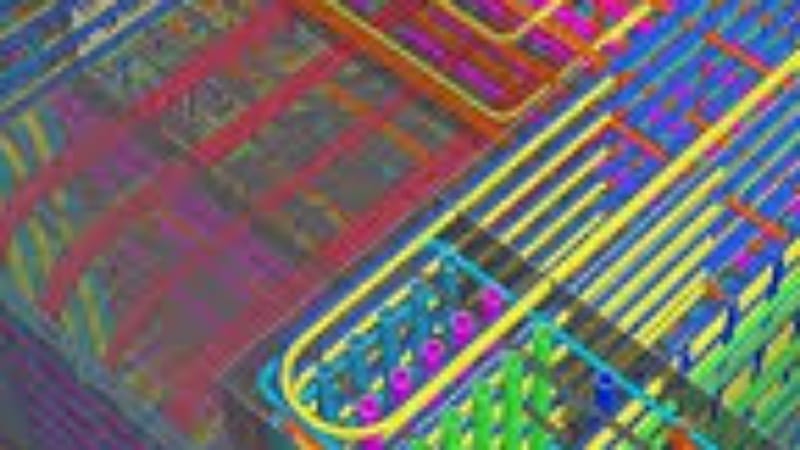

Many contractors rely on advanced visualization tools to understand how the steel will sit inside the concrete. These tools allow them to see the layout before placing a single bar. Clear diagrams also help field teams install the reinforcement faster because everything is already measured and mapped. This early clarity improves safety, reduces delays, and supports smoother project delivery.

Why Detailed Steel Layouts Matter

Steel reinforcement works with concrete to create a strong, durable foundation. Concrete alone is strong in compression but weak in handling tension. Steel handles that tension well. When both materials work together, they create a stable structure that can support heavy loads.

But for steel to work properly, it must be placed in the right position. Even a slight change in spacing, coverage, or alignment can affect the strength of the structure. That’s why detailed layouts help guide teams on-site.

Clear diagrams answer questions before they arise. They show exact bar sizes, spacing, overlaps, and bends. They also help ensure that the steel placed on-site matches the intent of the design engineers. Without these layouts, teams may guess leading to inconsistent results.

Builders who take time to understand detailed layouts often avoid common issues like congestion, misplaced bars, or improper lap lengths. These might seem small at first, but they can weaken the footing over time. Mistakes in a foundation take far more effort to repair than anything above ground.

Better Communication Across Project Teams

Construction involves many people. Architects, engineers, contractors, and inspectors all play a role. A simple misunderstanding can slow down a project or cause expensive rework. Clear steel layouts improve communication because everyone sees the same information in the same format.

These layouts also support better coordination between design teams and field crews. When workers understand what needs to be installed, they don’t need to interpret complex calculations or guess spacing on their own. This reduces confusion and keeps the project moving smoothly.

In the United States, where projects must meet strict building codes, clear layouts also help meet compliance requirements. Inspectors look for consistency, and precise steel placement makes that easier to achieve.

Supporting Loads and Preventing Settlement

Footings transfer loads from the structure to the soil. If the footing is weak or poorly supported, the entire structure can settle unevenly. In some cases, this can lead to cracks, uneven floors, and long-term structural issues.

Proper reinforcing steel helps footings resist bending and shear forces. When everything is placed correctly, the footing performs better under pressure. Steel layouts show the exact position of the bars, making it easier to meet load requirements.

Why Digital Tools Matter in Modern Construction

Digital tools have changed how steel layouts are planned. Rather than relying on hand-drawn sketches, teams now use advanced software to visualize reinforcement. This helps identify design conflicts early and ensures that the foundation can support all required loads.

Digital layouts also allow teams to share updates instantly. When changes are made, everyone sees them at the same time. This reduces the chance of installing outdated or incorrect information.

Around the United States, more builders are using digital layouts because they make projects faster and more cost-efficient. They also offer benefits like clash detection, which helps prevent problems before the concrete is poured.

These technologies also support better planning for rebar shop drawing services, which often rely on digital inputs. These services help convert design sketches into clear installation diagrams. They help teams understand exact bar lengths, configurations, and placement sequences. Having this level of detail improves accuracy and makes construction easier to manage.

Adding Value Through Better Project Planning

Planning is key to strong foundations. The more detailed the plan, the fewer mistakes and delays occur. Detailed layouts allow contractors to estimate materials accurately, plan labor needs, and schedule tasks efficiently.

Clear layouts also help reduce unplanned downtime. When workers know exactly what needs to be installed, they don’t lose time waiting for instructions. They also avoid removing or repositioning steel because everything is planned correctly the first time.

Better planning also reduces waste. Using the right amount of steel helps control costs and support more sustainable building practices. Many contractors in the United States appreciate this benefit because waste disposal has become more expensive in recent years.

When planning includes both engineers and installation crews, the final result becomes more reliable. Everyone understands their role, and each part of the foundation works as expected. This teamwork makes the project smoother and strengthens the final structure.

Professionals Who Understand Foundation Needs

Not all reinforcement work is the same. Footings require more attention because they carry such a heavy load. That’s why it’s important to work with professionals who understand how steel should be arranged and installed.

Experts help choose the right bar size, spacing, and layout. They also help identify design conflicts early. When teams collaborate with skilled professionals, foundations become safer and more predictable.

Many builders choose companies that offer detailed layout support, including digital diagrams and steel placement planning. This helps create a secure foundation and reduces the chance of future problems. Both help deepen understanding and make foundation work easier to manage.